Electrostatic discharge (ESD) can be a silent saboteur in cleanroom environments,

where even a minuscule discharge can compromise sensitive electronics and

delicate processes. Facility managers and decision-makers must ensure that their

cleanrooms adhere to stringent industry regulations while maintaining operational

efficiency. Selecting the right ESD solutions is paramount, but the process can be

daunting without the proper guidance.

Before delving into the specifics of ESD solutions, it is crucial to understand the

regulatory landscape. Industry standards such as ANSI/ESD S20.20 in the United

States and IEC 61340-5-1 globally provide comprehensive guidelines for ESD

control. These standards outline the necessary measures to mitigate ESD risks,

covering everything from flooring and work surfaces to personal grounding

equipment and ionization.

Compliance with these standards ensures the protection of sensitive equipment and enhances the reliability and longevity of your cleanroom operations. Regular audits and assessments are essential to verify compliance and identify areas for

improvement. By adhering to these guidelines, facility managers can create a robust framework for ESD control.

Every cleanroom has unique requirements based on its size, the nature of the

operations conducted, and the specific sensitivities of the equipment used.

Conducting a thorough assessment of your facility is the first step in selecting

appropriate ESD solutions. Consider the following factors:

● Type of Equipment and Materials: Identify the equipment and materials in

your cleanroom that are most susceptible to ESD damage. This includes

semiconductor devices, printed circuit boards, and other electronic

components.

● Environmental Conditions: Evaluate the temperature, humidity, and airflow

within your cleanroom. These factors can influence the effectiveness of ESD

control measures. For instance, lower humidity levels can increase the

likelihood of static buildup.

● Workflow and Layout: Analyze the workflow and layout of your cleanroom.

Areas with high foot traffic or frequent material handling may require more

robust ESD controls.

By understanding these requirements, you can tailor your ESD solutions to fit the

specific needs of your facility, ensuring optimal protection.

With a clear understanding of industry regulations and your facility’s requirements,

you can now focus on selecting the appropriate ESD solutions. Here are some key

areas to consider:

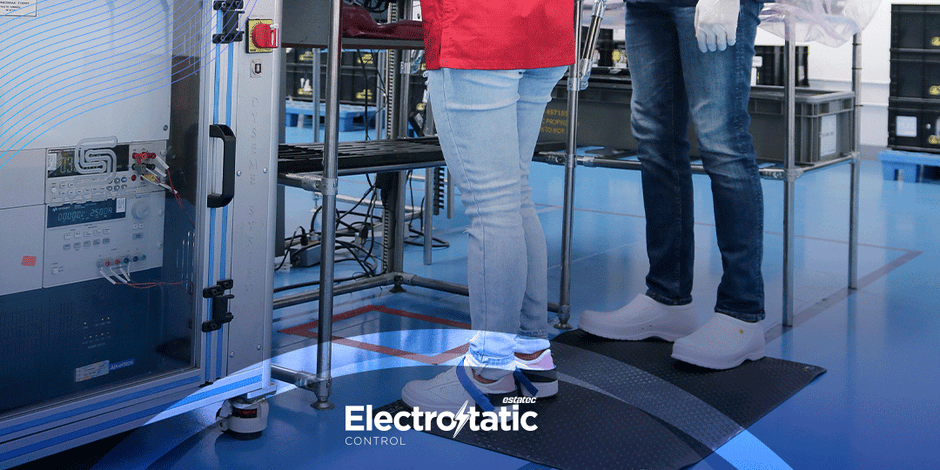

The right flooring is fundamental to effective ESD control. ESD flooring options

include conductive and dissipative flooring materials, each serving different

purposes. Conductive flooring provides a low-resistance path to ground, quickly

dissipating static charges, while dissipative flooring offers a higher resistance,

controlling the discharge rate.

When choosing ESD flooring, consider the following:

● Durability: Select materials that can withstand the demands of your cleanroom

environment, including chemical resistance and ease of maintenance.

● Installation: Ensure that the flooring installation adheres to ESD standards,

with proper grounding and sealing.

● Performance: Evaluate the flooring’s ability to maintain its ESD properties

over time, especially under varying environmental conditions.

● ESD Workstations

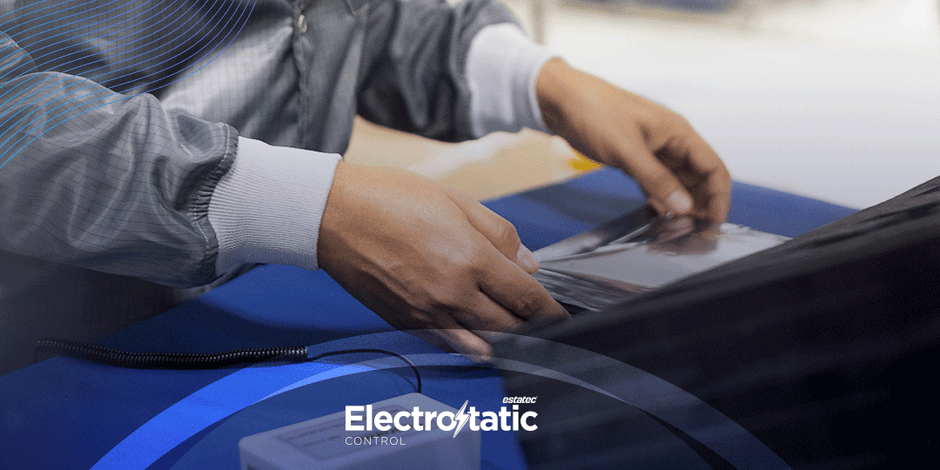

● Workstations are critical areas for ESD control, as they are where most

hands-on work occurs. ESD-safe workstations should include grounded work

surfaces, static-dissipative mats, and proper grounding points for personnel.

When setting up ESD workstations:

● Surface Materials: Use static-dissipative or conductive materials for

benchtops and mats. Ensure that all surfaces are properly grounded.

● Grounding Accessories: Equip workstations with wrist straps, heel grounders,

and grounding cords to protect personnel and equipment from static

discharge.

● Ionization: In areas where static buildup is significant, consider using ionizers

to neutralize static charges in the air and on surfaces.

● Personal Grounding Equipment

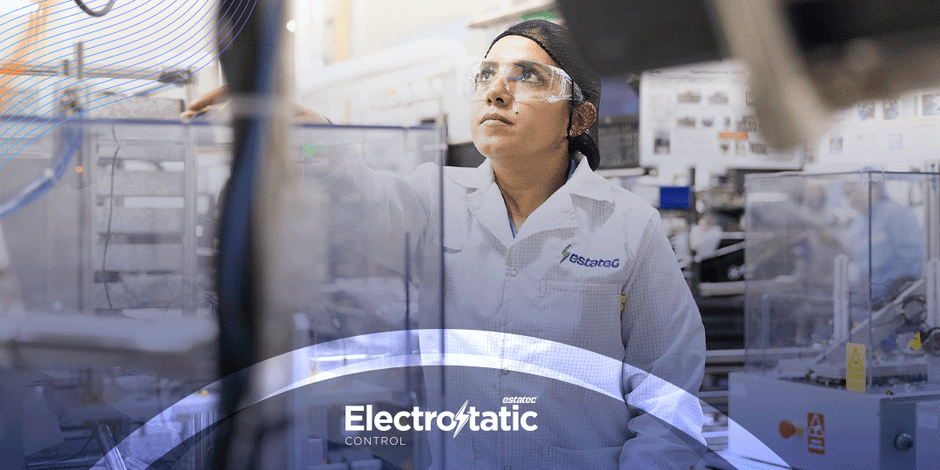

● Personnel are often the most significant source of static electricity in a

cleanroom.

Proper grounding equipment, such as wrist straps, heel

grounders, and conductive footwear, is essential to minimize ESD risks.