Electrostatic discharge (ESD) may be a modern electronics challenge, but

humanity has been wrestling with static electricity for centuries. The journey of

ESD protection, from rudimentary solutions to today’s advanced systems, reflects

our growing understanding of this invisible force and its impact on technology.

The Early Days:

The earliest approaches to ESD protection were, unsurprisingly, quite basic. As

industries noticed that static electricity could damage components or cause

hazardous sparks, grounding became the go-to method. By connecting objects and workers to the earth with conductive wires, static charges could be safely

dissipated. While effective, grounding alone wasn’t enough for the increasingly

sensitive electronics of the 20th century.

The Mid-20th Century:

The post-World War II era saw rapid advancements in electronics, particularly with the invention of the transistor in 1947. Suddenly, components became smaller, more delicate, and highly susceptible to ESD. The aerospace and defense industries were among the first to identify the need for better ESD controls, leading to the creation of anti-static materials, grounding wrist straps, and protective packaging.

The 1980s: Standardization and Static-Control Workstations

By the 1980s, ESD was recognized as a critical issue across industries.

Organizations like the ESD Association were formed to establish standards, such

as ANSI/ESD S20.20, ensuring consistent practices worldwide. Static-control

workstations became a common sight, equipped with:

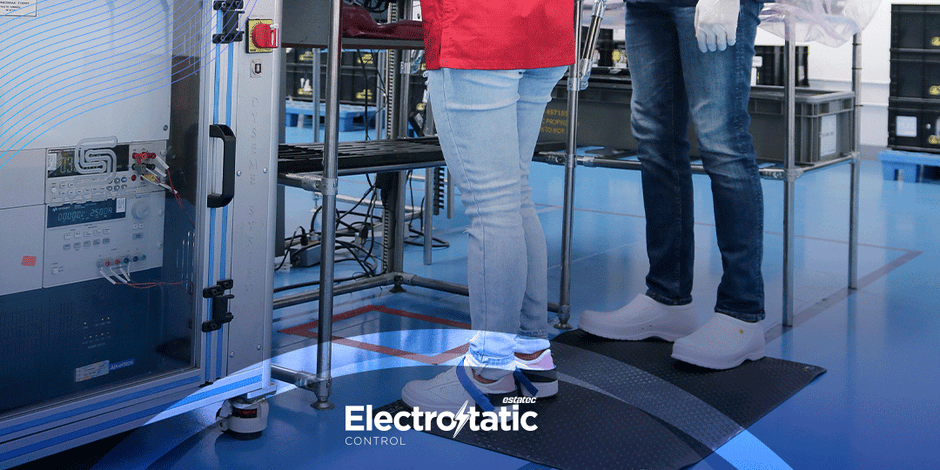

ESD mats

Grounding wrist straps

Estashoe

These measures significantly reduced ESD damage and became the foundation of modern ESD programs.

The 21st Century: Advanced ESD Systems

As electronics became even more miniaturized and complex, traditional ESD

measures needed reinforcement. Today’s systems combine multiple layers of

protection and cutting-edge technologies:

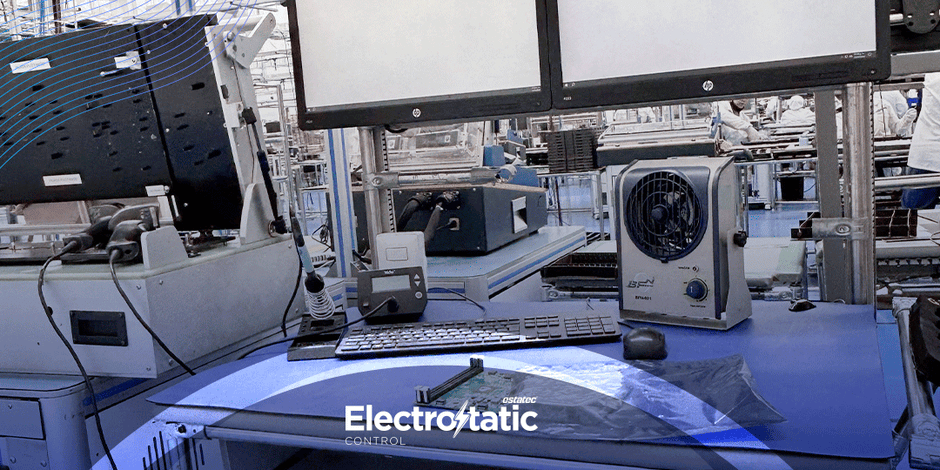

Ionizing Air Blowers: Neutralize airborne static, ideal for cleanrooms and

sensitive manufacturing.

Automated Monitoring Systems: IoT-enabled devices continuously track

ESD levels, ensuring consistent protection in real time.

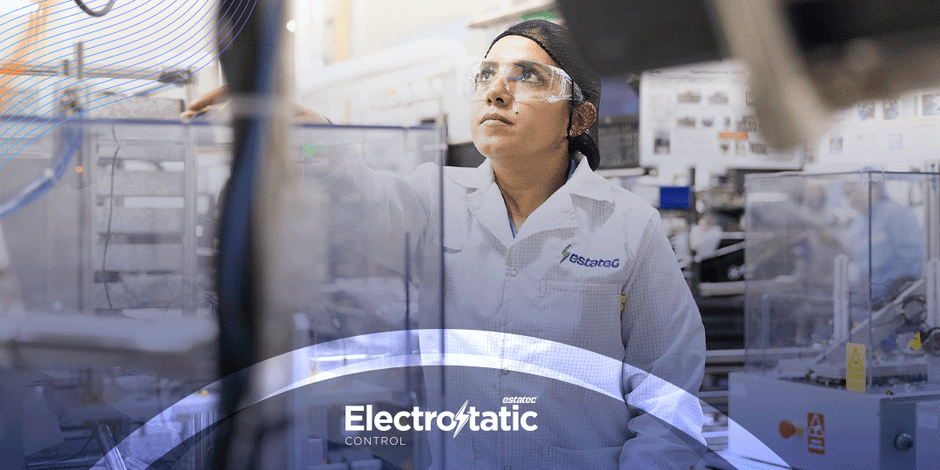

ESD Garments: High-tech fabrics with integrated conductive fibers prevent

static buildup on workers.

Static-Control Flooring: Entire facilities are designed with conductive flooring

to eliminate static risks at the source.

The Future:

The evolution of ESD protection isn’t over. With the rise of Industry 4.0, ESD

systems are becoming smarter and more integrated. Wearable technology, AI-

driven monitoring, and eco-friendly materials are shaping the next generation of

protection. These advancements ensure that even as electronics continue to

shrink, their safety grows.