When it comes to selecting ESD flooring, making the right choice is crucial for maintaining a safe and productive environment. Here is a comprehensive guide to help you navigate the selection process across various industries:

Step 1: Assess Your Risk Level. Before diving into flooring options, it is essential to evaluate the risk level associated with your industry:

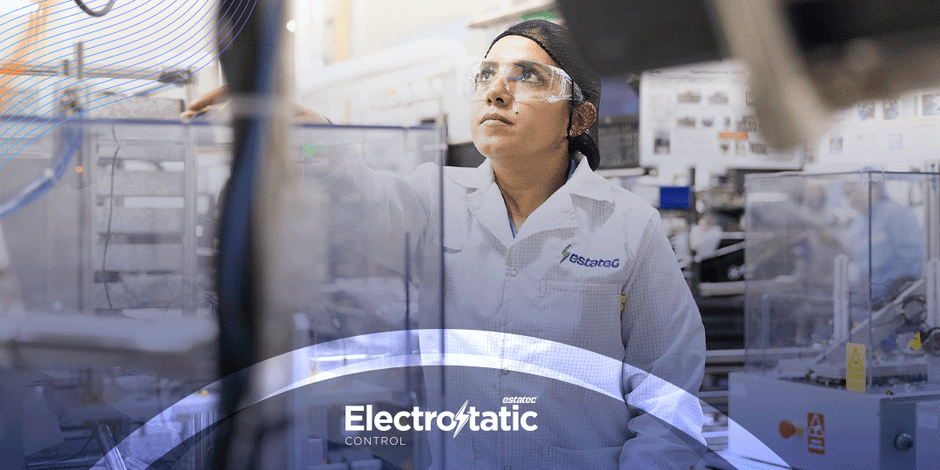

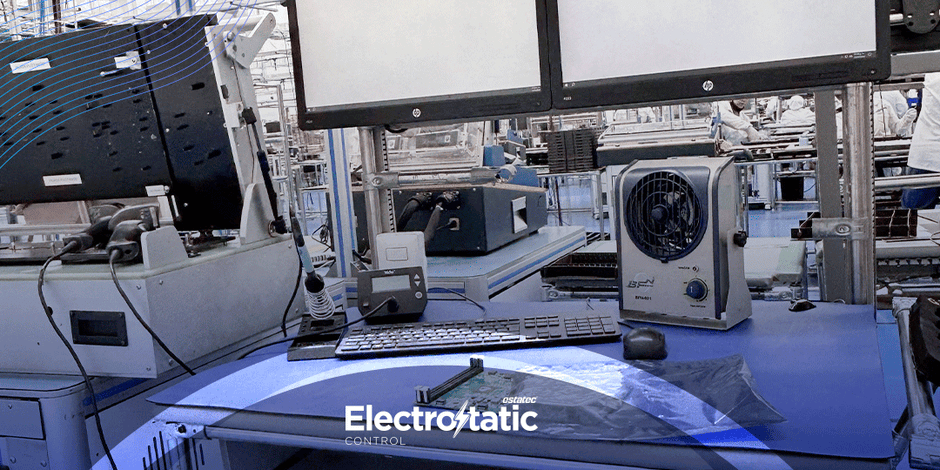

High Risk: Industries such as electronics manufacturing, semiconductor manufacturing, and cleanroom facilities deal with delicate electronics and are highly susceptible to ESD-related damage or fire hazards.

Medium Risk: Environments like storage areas for electronic components may encounter occasional ESD concerns, requiring a moderate level of static control.

Low Risk: Areas such as offices, common rooms, or non-electronic manufacturing spaces have minimal static dangers and may only require basic static control measures.

Step 2: Understand ESD Flooring Types. Once you have assessed your risk level, familiarize yourself with the two main categories of ESD flooring:

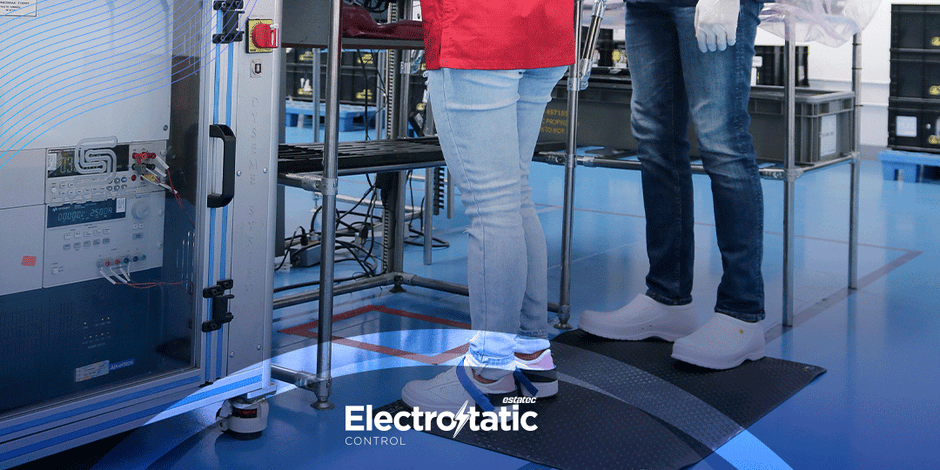

Conductive Flooring: Designed to rapidly dissipate static charges with low resistance. Ideal for high-risk environments but requires proper footwear to prevent shocks.

Static Dissipative Flooring: Gradually dissipates static charges, offering better shock protection than conductive flooring. Suitable for medium-risk areas.

Step 3: Consider Additional Factors.

Flooring Material: Choose from options such as tile, sheet vinyl, and ESD carpet tiles, each offering unique advantages in terms of durability, installation ease, and cleanability.

Footwear: Ensure that personnel wear ESD-safe footwear to maintain proper grounding and minimize the risk of shocks.

Grounding System: The effectiveness of the ESD flooring relies on a robust grounding system to safely dissipate static charges.

Pro Tip: Do not Overlook ESD Seating. While selecting ESD flooring is crucial, do not forget about ESD chairs and stools. These specialized seating options ensure that personnel remain properly grounded, enhancing overall static control measures in your facility. Consulting with an experienced ESD specialist can provide valuable insights to make an informed decision and safeguard your facility against static-related hazards.