Electrostatic discharge (ESD) poses a significant threat to product integrity and

reliability in electronics manufacturing and sensitive environments. To mitigate this

risk, the use of ESD smocks has become essential. These specialized garments

control and dissipate static charges, providing a vital layer of protection in

electrostatic control programs.

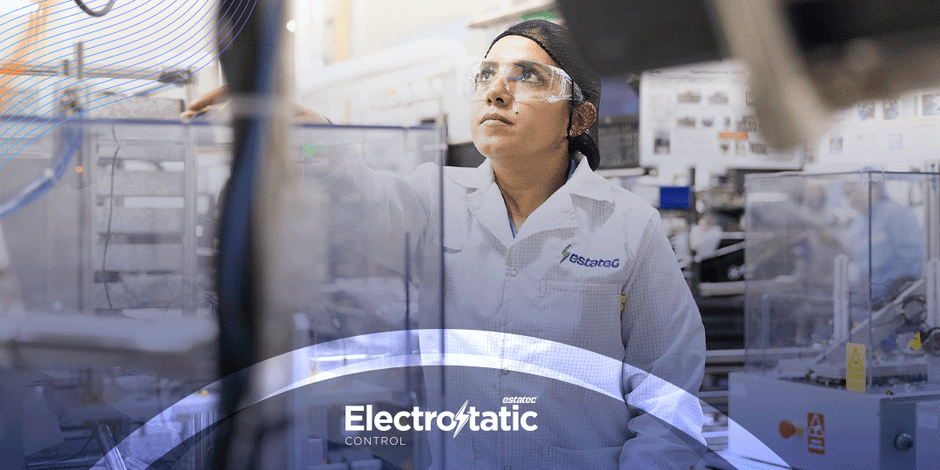

ESD smocks serve as a critical defense against ESD events. Engineered with

conductive or dissipative materials, they safely channel and discharge static

charges away from the wearer’s body. By minimizing the potential for ESD events,

ESD smocks help maintain product integrity and reduce the risk of costly failures.

Innovative Design and Features.

ESD smocks are meticulously designed to meet specific industry standards and

requirements. They feature conductive fibers, grounding systems, and adjustable

closures to ensure a proper fit. Available in a range of styles like lab coats, jackets,

or shirts, ESD smocks cater to diverse applications and environments. These

designs ensure that workers are comfortable and protected, enhancing their

effectiveness in controlling ESD risks.

Integration into ESD Control Programs.

ESD-safe smocks are integral to comprehensive electrostatic control programs,

which include measures such as personnel grounding, controlled environments,

surface grounding, and proper handling procedures. By wearing ESD smocks,

operators and technicians can effectively minimize the introduction of ESD events

that could compromise sensitive electronics. This added layer of protection

ensures personnel are grounded and static charges are dissipated effectively.

Compliance and Industry Standards.

The use of ESD smocks aligns with industry-specific standards and regulations.

Compliance with these standards is crucial to maintaining the effectiveness of

electrostatic control programs and ensuring product quality. Organizations must

ensure that their chosen ESD smocks meet required standards and undergo

regular performance testing to guarantee their effectiveness.

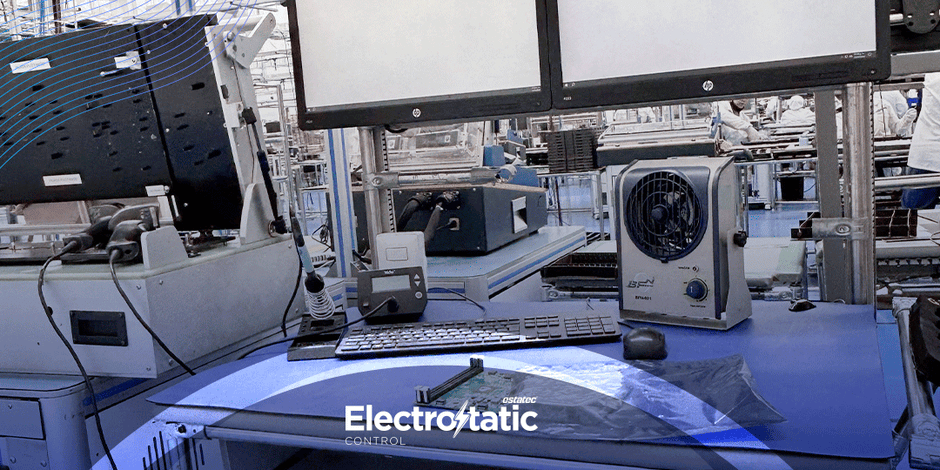

By dissipating static charges and providing a controlled grounding path, ESD

smocks play a vital role in maintaining product integrity, reducing costly failures,

and upholding quality standards in electronic manufacturing environments.

Incorporating ESD smocks into comprehensive electrostatic control programs is an

initiative-taking step towards ensuring the reliability and longevity of electronic

products.