In environments where electrostatic discharge (ESD) poses a risk to sensitive

electronic equipment, protective measures are indispensable. One often overlooked

yet highly effective tool in preventing ESD is the heel grounder. This small,

unobtrusive accessory plays a significant role in protecting both equipment and

employees in industries where static buildup can cause damage or even hazardous

situations.

What Exactly Are Estaheel Grounders?

Heel grounders are wearable devices designed to prevent static electricity from

building up on a person. They are typically made of a conductive rubber or fabric

strap that wraps around the heel of a shoe, along with a conductive ribbon that

makes direct contact with the skin or sock of the wearer. The goal is to create a

continuous path through which static charges can dissipate safely to the ground,

reducing the risk of electrostatic discharge.

Unlike wrist straps, which require a direct connection to an ESD-safe surface, heel

grounders offer hands-free convenience. This makes them ideal for workers who

need the freedom to move around without constantly reconnecting themselves to

grounded equipment.

How Do Estaheel Grounders Work?

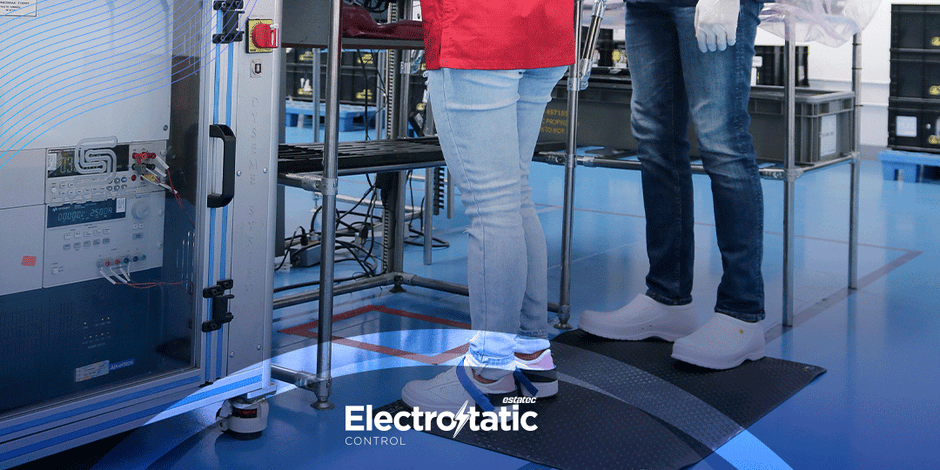

Heel grounders work by allowing static electricity to flow from the body to the floor,

ensuring that charges do not accumulate to dangerous levels. When a person wears a heel grounder, the conductive strap maintains contact with the floor surface, usually through specially designed ESD-safe flooring. The conductive ribbon or strip that tucks into the shoe allows any static charge from the body to transfer downwards, through the grounder, and safely into the ground.

This system is based on the principle of grounding, where electricity naturally flows

from areas of higher charge to areas of lower charge (the ground). By wearing heel

grounders, workers avoid becoming walking static bombs that could inadvertently

cause damage to sensitive electronics or ignite flammable materials.

When Are Estaheel Grounders Necessary?

Heel grounders are indispensable in environments where controlling ESD is

paramount. This includes industries such as electronics manufacturing, aerospace,

pharmaceuticals, and cleanrooms, where even a tiny spark can cause significant

damage or failure. For instance, in a factory that assembles microchips, a single

electrostatic discharge could destroy an entire batch of components, resulting in

substantial financial losses.

Similarly, in medical and pharmaceutical environments, where sterile conditions and

precision are non-negotiable, heel grounders help prevent ESD from contaminating

delicate processes or equipment. These devices are also commonly used in

cleanrooms, where airborne particles and electrostatic discharge can interfere with

controlled environments.

Why Choose Estaheel Grounders?

While there are several methods for controlling ESD, heel grounders offer unique

benefits that make them a popular choice in industrial settings:

● Mobility: Workers can move freely without being tethered to a workstation.

This increases productivity, especially in large facilities where employees

need to travel between different areas.

● Dual Foot Protection: Most heel grounders are used in pairs, one for each

foot. This ensures that the worker remains grounded even when lifting one

foot off the floor.

● Cost-Effective: Heel grounders are relatively inexpensive compared to other

grounding solutions like conductive footwear. For companies looking for

budget-friendly ways to meet ESD safety requirements, estaheel grounders are an

efficient option.

● Ease of Use: They are simple to put on and take off, requiring minimal training

or adjustment. Workers can quickly strap on their heel grounders and get to

work.

● Comfort: Modern heel grounders are designed with comfort in mind. Many are

adjustable, and their low-profile design means they don’t interfere with the

worker’s normal range of motion.

Proper Use and Maintenance of Heel Grounders

While heel grounders are straightforward in their function, proper use and

maintenance are essential to ensure effectiveness. Workers must always ensure that the conductive strip is securely placed inside their shoe, making contact with their sock or foot. If the strip is not making contact, the device cannot dissipate static electricity properly.

Additionally, heel grounders should be regularly tested to ensure they are functioning correctly. Over time, the materials in the grounder may degrade, reducing their ability to conduct electricity. Routine testing helps catch these issues before they become a problem.

Finally, heel grounders work best when paired with ESD-safe flooring. Without an

appropriate grounding surface, the grounder has no path to dissipate the static

charge. In environments without ESD-safe floors, alternative grounding methods like wrist straps or conductive footwear may be necessary.