When working in environments where electrostatic discharge (ESD) can be a risk, it's essential to choose materials that provide the right level of protection. Among these materials, static dissipative and conductive options are frequently mentioned.

Though both play a role in managing static electricity, they serve distinct purposes.

Understanding the difference between them is key to ensuring the proper level of

safety for sensitive electronics and components.

What is Electrostatic Discharge (ESD)?

Before talking about the materials themselves, it helps to briefly touch on what ESD

is. In simple terms, ESD refers to the sudden flow of electricity between two objects, often resulting in a spark. While that might seem like a small occurrence, this spark can wreak havoc on sensitive electronic devices. Preventing the buildup and sudden discharge of static electricity is where static dissipative and conductive materials come into play.

Conductive Materials: The Fast Track for Static Electricity

Conductive materials are designed to allow electrical charges to move easily through them. Think of them as express lanes for electricity. These materials have a very low electrical resistance, typically less than 1 x 10^4 ohms, which enables them to rapidly transfer electrical charges to the ground or another conductive surface.

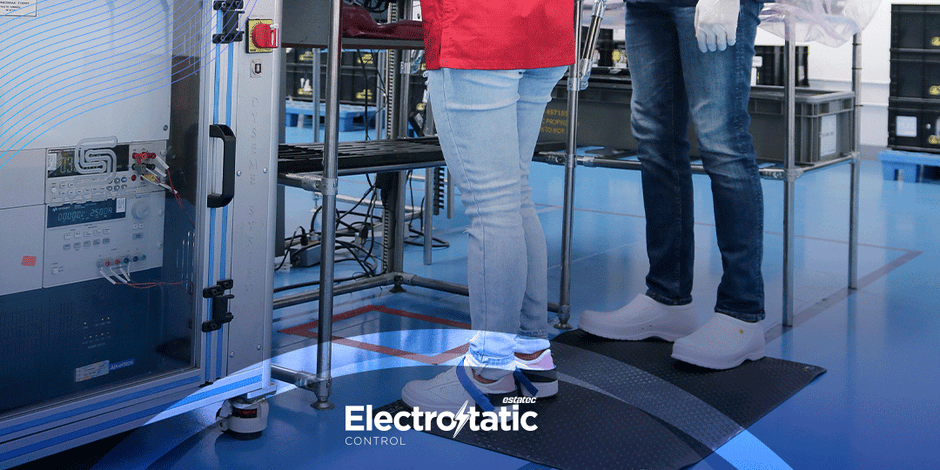

In an ESD-protected area, conductive materials are often used in things like mats,

wrist straps, and flooring. By providing a low-resistance path, conductive materials

help ensure that any static electricity is safely discharged, minimizing the risk of

damaging sensitive equipment. However, the speed at which they transfer static can be a drawback in certain applications. If the charge moves too quickly, it could result in an ESD event, which is why conductive materials are often paired with other protective solutions.

Static Dissipative Materials: A Smoother Discharge Path

On the other hand, static dissipative materials allow static electricity to move more

slowly. With resistance typically ranging from 1 x 10^6 ohms to 1 x 10^11 ohms,

these materials provide a middle ground between insulative and conductive

materials. Instead of rapidly transferring static charges like conductive materials do,

static dissipative ones spread the charge out and discharge it at a controlled,

moderate rate.

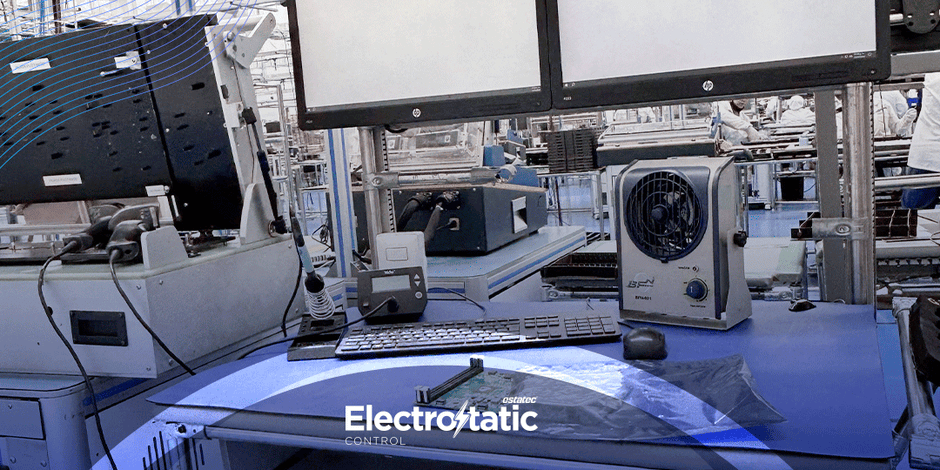

This controlled discharge helps prevent sudden spikes in electricity, which could

damage sensitive devices. In many environments, such as cleanrooms or assembly

lines, static dissipative materials are preferred because they reduce the risk of ESD

events without transferring charges too quickly. You’ll find static dissipative materials used in items like ESD-safe bags, tool handles, and certain work surfaces.

How Do They Compare?

While both materials help prevent electrostatic buildup and discharge, they differ in

how they manage the flow of electricity:

● Electrical Resistance: Conductive materials have low resistance, which allows

charges to flow quickly. Static dissipative materials have higher resistance,

allowing for a slower, controlled flow of electricity.

● Speed of Discharge: Conductive materials provide rapid discharge of static,

while static dissipative materials discharge more gradually, reducing the risk

of an ESD event.

● Applications: Conductive materials are typically used where rapid grounding is

essential, such as in wrist straps and floor mats. Static dissipative materials,

by contrast, are favored in environments where controlling the rate of static

discharge is important, such as in packaging and work surfaces.

When to Use Each Material

Choosing between static dissipative and conductive materials depends on the

specific needs of your environment. Conductive materials are excellent when fast

discharge of static electricity is critical, especially when working with equipment

designed to handle these rapid shifts. However, if you're working with delicate

electronics or in an environment where even small static shocks can be harmful,

static dissipative materials are often a safer choice because of their ability to release charges in a controlled manner.

A Balanced Approach

In many cases, ESD protection involves using a combination of both materials.

Conductive products like mats and wrist straps can work in tandem with static

dissipative surfaces and tools to create a well-rounded ESD-safe environment. The

key is to balance the speed of discharge with the sensitivity of the equipment being

handled.